新聞中心

滾珠絲杠常見加工工藝分析

來源:http://www.zsdress.com/ 日期:2021-02-02 發布人:

目前的市場上,滾珠絲桿的加工方法大致分為兩種:1、有屑加工(切削成形);2、無屑加工(塑性加工)。前者主要有車削旋風銑削等,后者則包含冷擠壓、冷軋等。今天來簡單談一談這兩個加工方法:

In the current market, there are two machining methods for ball screw: 1. Chip machining (cutting forming); 2. Chip free machining (plastic machining). The former mainly includes turning and whirlwind milling, while the latter includes cold extrusion and cold rolling. Today, let's talk about these two processing methods

一、有屑加工

1、 Chip processing

絲桿有屑加工指利用切削成形的方法加工絲桿,主要有車削、旋風銑削。

The machining of screw rod with chip refers to the machining of screw rod by cutting forming method, mainly including turning and whirlwind milling.

車削:車削是在車床使用不同的車刀或其他刀具,可以加工各種回轉表面,如內外圓柱面、內外圓錐面、螺紋、溝槽、端面和成形面等,加工精度可達IT8-IT7,表面粗糙度Ra值為1.6-0.8,車削常用來加工單~軸線的零件,如直軸和盤、套類零件等。

Turning: turning is the use of different turning tools or other tools in the lathe, which can process various rotary surfaces, such as internal and external cylindrical surface, internal and external conical surface, thread, groove, end face and forming surface. The machining accuracy can reach it8-it7, and the surface roughness Ra value is 1.6-0.8. Turning is commonly used to process single axis parts, such as straight axis, disc and sleeve parts.

旋風切削:旋風切削是一種率的螺紋加工方法,適用于批量較大的螺紋粗加工,其工藝是用硬質合金刀對螺紋進行高速銑削,它具有刀具冷卻好、生產效率高的優點。精度要求不高的螺紋,可用此法一次完成切削加工。

Whirlwind cutting: whirlwind cutting is a high-efficiency thread processing method, which is suitable for large batch of thread rough machining. Its process is high-speed milling of thread with cemented carbide cutter. It has the advantages of good tool cooling and high production efficiency. This method can be used to finish the machining of thread with low precision.

二、無屑加工

2、 Chip free machining

絲桿無屑加工指利用金屬塑性成形的方法加工絲桿,主要有冷擠壓、冷軋。

Lead screw chip free processing refers to the use of metal plastic forming method to process lead screw, mainly including cold extrusion and cold rolling.

冷擠壓:冷擠壓就是把金屬毛坯放在冷擠壓模腔中,在室溫下,通過壓力機上固定的凸模向毛坯施加壓力,使金屬毛坯產生塑性變形而制得零件的加工方法。目前我國研制的冷擠壓件一般尺寸精度可達8-9級。

Cold extrusion: cold extrusion is to put the metal blank in the cold extrusion die cavity, at room temperature, through the punch fixed on the press to exert pressure on the blank, so that the metal blank has plastic deformation and parts are made. At present, the general dimension accuracy of cold extrusion parts developed in China can reach 8-9 grades.

冷軋:冷軋是在常溫狀態下由熱軋板加工而成,雖然在加工過程因為軋制也會使鋼板升溫,盡管如此還是叫冷軋。滾珠絲桿螺紋滾道的冷軋成形過程是軋輥與金屬圓棒料之間形成的摩擦力,在螺旋壓力的推動下使金屬棒料被咬入滾軋區,然后在軋輥的強制滾壓力作用下產生塑性變形的過程。

Cold rolling: cold rolling is made of hot-rolled plate at room temperature. Although in the processing process, because rolling will also make the steel plate warm, it is still called cold rolling. The cold rolling forming process of the ball screw thread raceway is a process in which the friction force between the roll and the metal round bar is formed, and the metal bar is bited into the rolling area under the push of the spiral pressure, and then the plastic deformation is produced under the action of the forced rolling pressure of the roll.

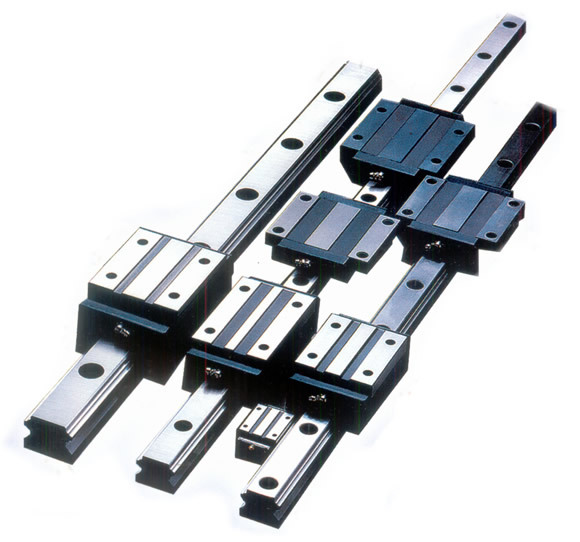

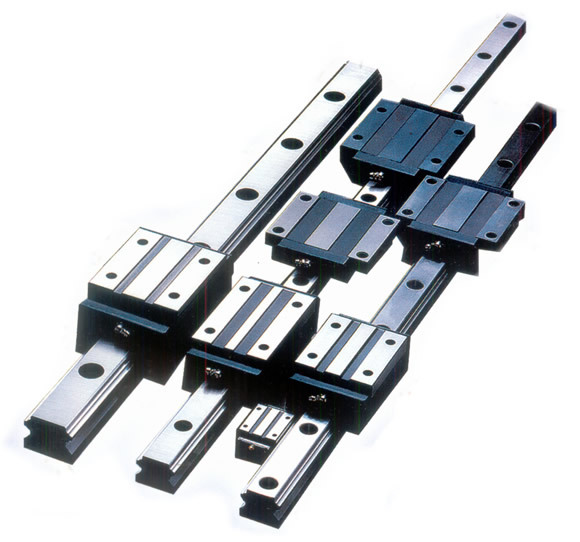

- 上一篇:導軌絲杠的市場發展分析

- 下一篇:絲桿和導軌的級別是如何區分的?

導軌絲杠:從設計結構...<>

導軌絲杠:從設計結構...<> 大型絲杠的性能設計介...<>

大型絲杠的性能設計介...<> 梯形絲杠和滾珠絲杠的...<>

梯形絲杠和滾珠絲杠的...<> 滾珠絲桿目前的行業的...<>

滾珠絲桿目前的行業的...<> 滾珠絲杠螺母油封更換...<>

滾珠絲杠螺母油封更換...<>

相關: