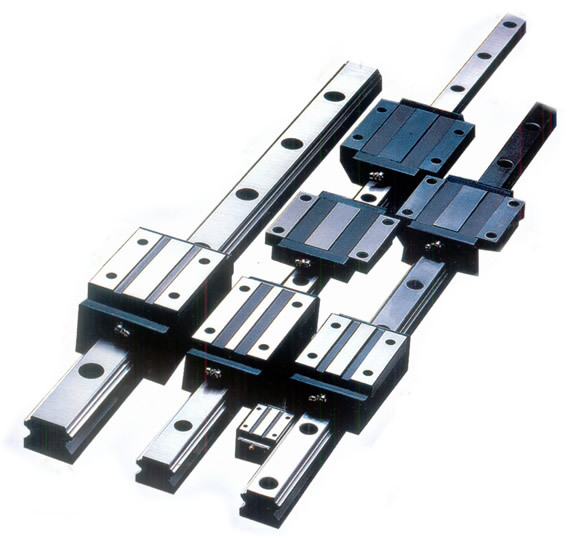

解析導軌運行平穩度標準

來源:http://www.zsdress.com/ 日期:2025-05-14 發布人:

檢測方法

Testing method

直線度檢測:常用的直線度檢測方法有拉鋼絲法、激光準直儀法等。拉鋼絲法是通過在導軌兩端拉一根細鋼絲,然后使用千分表在導軌上移動,測量鋼絲與導軌之間的距離變化,從而判斷導軌的直線度誤差。激光準直儀法則利用激光的高準直性,通過測量激光束與導軌的偏差,精確檢測直線度。

Straightness detection: Common straightness detection methods include wire drawing method, laser collimator method, etc. The wire pulling method is to pull a thin wire at both ends of the guide rail, and then move it on the guide rail using a dial gauge to measure the distance change between the wire and the guide rail, in order to determine the straightness error of the guide rail. The laser collimator principle utilizes the high straightness of lasers to accurately detect straightness by measuring the deviation between the laser beam and the guide rail.

平行度檢測:采用千分表或百分表配合標準平尺或量塊進行檢測。將千分表固定在運動部件上,使其測頭與基準導軌或平尺表面接觸,然后移動運動部件,讀取千分表的讀數變化,以此確定導軌之間的平行度誤差。

Parallelism testing: Use a micrometer or dial gauge in conjunction with a standard ruler or measuring block for testing. Fix the dial gauge on the moving part so that its measuring head is in contact with the surface of the reference rail or ruler, then move the moving part and read the reading change of the dial gauge to determine the parallelism error between the rails.

垂直度檢測:使用直角尺、垂直度測量儀等工具進行檢測。將直角尺或垂直度測量儀放置在導軌與相關部件之間,通過測量兩者之間的間隙或角度偏差,判斷垂直度是否符合要求。

Verticality detection: Use tools such as a square ruler and verticality measuring instrument for detection. Place a ruler or verticality measuring instrument between the guide rail and related components, and determine whether the verticality meets the requirements by measuring the gap or angle deviation between the two.

表面粗糙度檢測:可采用觸針式粗糙度測量儀或光學顯微鏡等設備進行檢測。觸針式粗糙度測量儀通過觸針在導軌表面移動,測量表面微觀輪廓的起伏,從而得出表面粗糙度數值;光學顯微鏡則通過觀察導軌表面的微觀形貌,對表面粗糙度進行定性和定量分析。

Surface roughness detection: It can be carried out using equipment such as a stylus roughness measuring instrument or an optical microscope. The stylus roughness measuring instrument measures the roughness value of the surface by moving the stylus on the surface of the guide rail, measuring the roughness of the micro profile of the surface; The optical microscope qualitatively and quantitatively analyzes the surface roughness by observing the microstructure of the guide rail surface.

評估標準

Evaluation criteria

不同行業和應用場景對導軌運行平穩度的評估標準有所差異。在機床制造行業,一般要求導軌的直線度誤差在每米 0.01 - 0.03 毫米之間,平行度誤差不超過 0.02 毫米;電梯行業中,導軌的垂直度誤差每 5 米不應超過 1 毫米,直線度誤差每米不超過 0.05 毫米。此外,對于高精度的自動化設備,對導軌的各項精度指標要求更為嚴格。這些標準是根據設備的功能需求、運行性能和要求制定的,確保導軌在實際使用中能夠滿足設備的正常運行和精度要求。

The evaluation criteria for the smoothness of guide rail operation vary among different industries and application scenarios. In the machine tool manufacturing industry, it is generally required that the straightness error of the guide rail be between 0.01-0.03 millimeters per meter, and the parallelism error not exceed 0.02 millimeters; In the elevator industry, the verticality error of the guide rail should not exceed 1 millimeter per 5 meters, and the straightness error should not exceed 0.05 millimeters per meter. In addition, for high-precision automation equipment, the requirements for various precision indicators of the guide rail are more stringent. These standards are formulated based on the functional requirements, operational performance, and safety requirements of the equipment, ensuring that the guide rail can meet the normal operation and accuracy requirements of the equipment in actual use.

本文由導軌絲杠友情奉獻.更多有關的知識請點擊:http://www.zsdress.com真誠的態度.為您提供為的服務.更多有關的知識我們將會陸續向大家奉獻.敬請期待.

This article is a friendly contribution from the guide screw For more information, please click: http://www.zsdress.com Sincere attitude To provide you with comprehensive services We will gradually contribute more relevant knowledge to everyone Coming soon.

- 上一篇:絲杠動態剛度怎么測?

- 下一篇:解析導軌抗磨損涂層技術

導軌絲杠:從設計結構...<>

導軌絲杠:從設計結構...<> 大型絲杠的性能設計介...<>

大型絲杠的性能設計介...<> 梯形絲杠和滾珠絲杠的...<>

梯形絲杠和滾珠絲杠的...<> 滾珠絲桿目前的行業的...<>

滾珠絲桿目前的行業的...<> 滾珠絲杠螺母油封更換...<>

滾珠絲杠螺母油封更換...<>