新聞中心

為什么導(dǎo)軌絲桿中頻淬火后會出現(xiàn)磨削裂紋?

來源:http://www.zsdress.com/ 日期:2021-03-31 發(fā)布人:

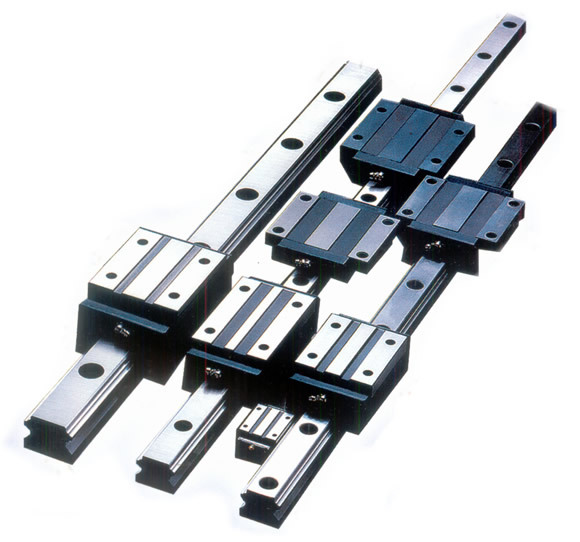

目前,精密導(dǎo)軌絲桿采用中頻感應(yīng)淬火。在生產(chǎn)中,淬火(回火)絲桿磨削螺紋后,螺紋滾道弧面上常出現(xiàn)軸向或網(wǎng)狀裂紋。

At present, medium frequency induction hardening is used for precision guide screw. In production, axial or network cracks often appear on the arc surface of thread raceway after grinding thread with quenched (tempered) screw rod.

即使在精密導(dǎo)軌絲桿的過程中,也只有肉眼才能發(fā)現(xiàn)裂紋,導(dǎo)致精密導(dǎo)軌絲桿報(bào)廢。這不僅給企業(yè)造成了直接的經(jīng)濟(jì)損失,而且由于各種因素的影響,給企業(yè)生產(chǎn)帶來了更大的壓力。

Even in the process of the precision guide screw, only the naked eye can find the cracks, leading to the scrapping of the precision guide screw. This not only causes direct economic losses to enterprises, but also brings greater pressure to enterprise production due to various factors.

1.精密導(dǎo)軌絲桿原料不好

1. The raw material of precision guide screw is not good

主要原因是ccr15材料網(wǎng)狀碳化物的退火組織不合格(含片狀珠光體)。通過對裂紋盤條中碳化物的不均勻性和顯微組織的分析,發(fā)現(xiàn)網(wǎng)狀碳化或球化退火組織不良的盤條不合格,約占總數(shù)的40%。

The main reason is that the annealed microstructure of network carbide in ccr15 material is unqualified (containing flake pearlite). Through the analysis of the inhomogeneity and microstructure of carbide in cracked wire rod, it is found that the wire rod with poor network carbonization or spheroidizing annealing structure is unqualified, accounting for about 40% of the total.

碳化物的不均勻性導(dǎo)致感應(yīng)淬火后表面硬度和內(nèi)應(yīng)力分布不均,內(nèi)應(yīng)力也集中在碳化物集中的部位。螺桿磨削時,由于各零件的內(nèi)應(yīng)力大于材料的屈服強(qiáng)度,會產(chǎn)生磨削裂紋。精密導(dǎo)軌絲桿狀珠光體的存在導(dǎo)致感應(yīng)淬火后螺桿表面晶粒粗大,降低了鋼的屈服強(qiáng)度。螺桿拋光時,在內(nèi)應(yīng)力超過材料屈服強(qiáng)度的部位會產(chǎn)生磨削裂紋。

The inhomogeneity of carbides leads to the uneven distribution of surface hardness and internal stress after induction hardening, and the internal stress is also concentrated in the carbides concentrated position. When the screw is ground, because the internal stress of each part is greater than the yield strength of the material, grinding cracks will occur. The existence of rod-shaped pearlite in precision guide leads to the coarsening of the surface grains of the screw after induction hardening, which reduces the yield strength of the steel. When the screw is polished, grinding cracks will appear at the position where the internal stress exceeds the yield strength of the material.

2.精密導(dǎo)軌絲桿螺桿中頻淬火熱處理不良

2. Poor intermediate frequency quenching heat treatment of precision guide screw

主要表現(xiàn)為淬火溫度高或回火不足。通過分析統(tǒng)計(jì),絲杠磨削裂紋約占絲杠磨削裂紋總數(shù)的20%-30%。

It is mainly characterized by high quenching temperature or insufficient tempering. Through analysis and statistics, the grinding cracks of lead screw account for about 20% - 30% of the total number of grinding cracks.